| Custom manufacturing of heater block begins with raw copper material, which is purchased in large rolls and sold by the manufacturer in bulk by the ton. The rolls can be procured in two thicknesses. Fin material is .0025″ thick, while the tube material is .0045″ thick. Also 25/75 lead solder is used in the process. |

|

|

Along with the copper and solder, several pieces of equipment are necessary for the production of the blocks. The first machine used in the process of manufacturing cellular block is a tube mill, which takes the .0045″ copper strip and forms the corrugated tube. The copper strip goes into the machine as a flat piece of copper and comes out looking like a tube for a cellular core. |

| Universal Carnegie Manufacturing has two tube mills, each using a different width of raw copper. This allows for the simultaneous manufacturing of tubes of two different widths. |

|

|

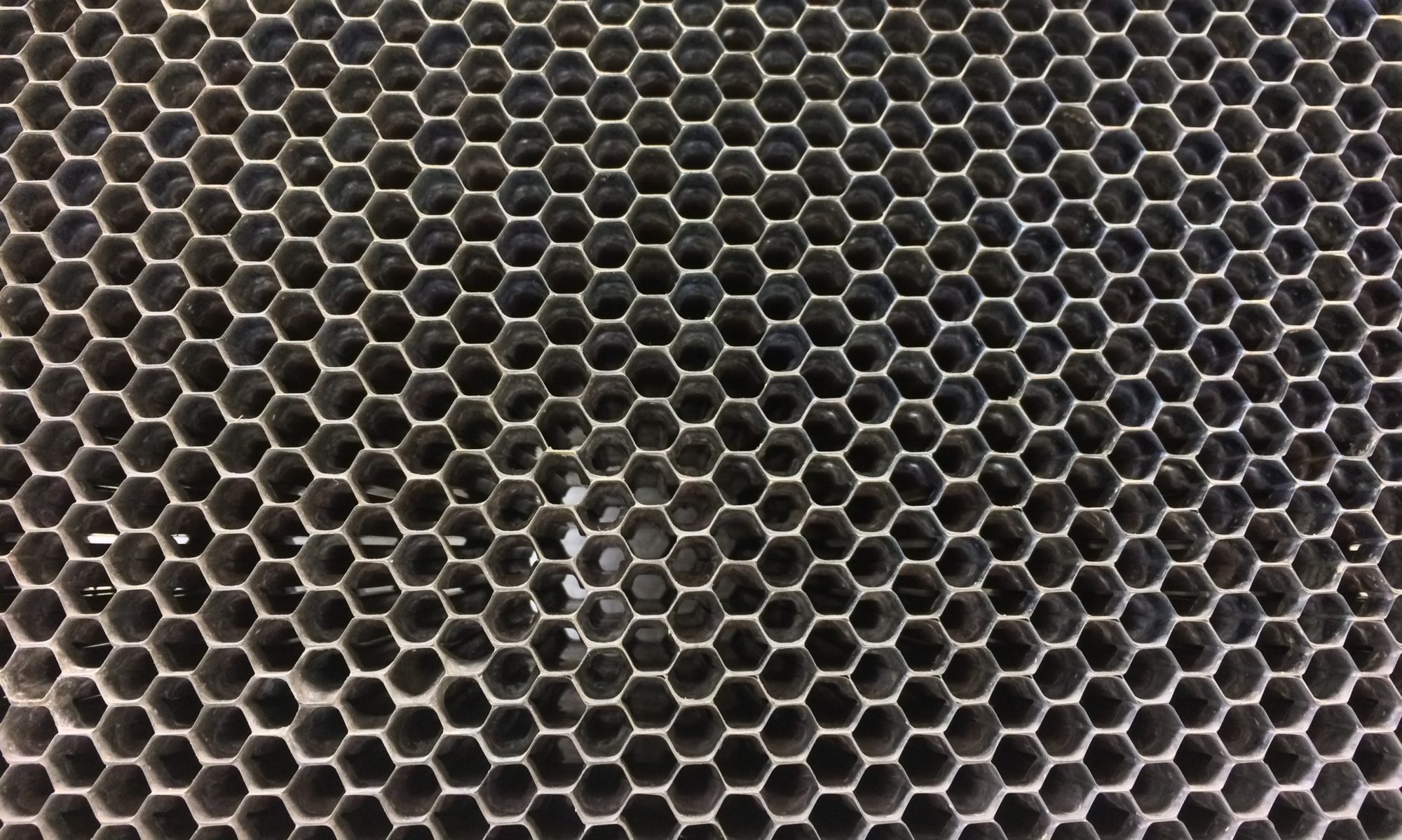

Another machine is capable of manufacturing fins of all four sizes. This machine corrugates the fins that will fit between the tubes and dissipate the heat. Strips of .0025″ copper are fed into the fin mill and corrugated fins are produced. |

| After the tubes and fins have been formed they must be assembled. The tubes and fins are prepared for seaming by cutting them down to the size required for the heater core being manufactured. Once completed, the tubes are ready to go into the seamer. |

|

|

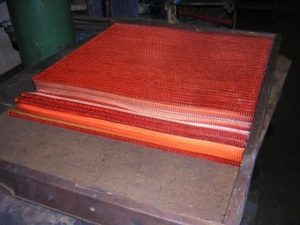

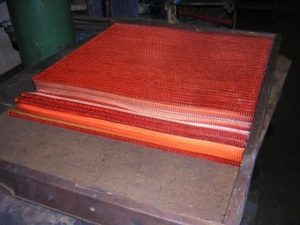

Once all of the fins and tubes are prepared, they are stacked together to the specific width that is required by the customer for whom the order is being prepared. |

| To finalize the assembly of the cellular block, the solder is heated in a tray to a temperature of 900°F. After heating for approximately three hours, the tray is filled to capacity and then scraped clean to eliminate imperfections (dead spots) in the solder. |

|

|

One side of the block is dipped in the flux. |

| It is then dipped in the solder. After one side of the block is dipped, the other side goes through the same process. |

|

|

Once the unit has cooled, it is ready to be boxed and shipped to the customer. |